What are the benefits of optimizing transport routes?

-

3 min read

•

17 Oct 2022

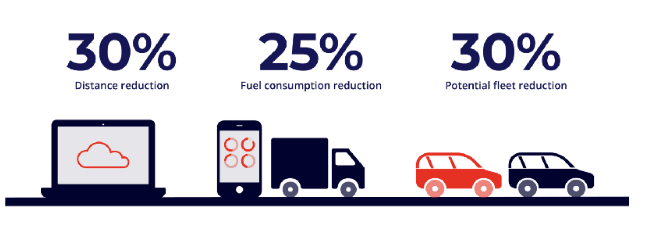

By using a smart routing solution, a large retail chain experienced an up to 30% reduction in vehicles required to complete all their daily operations. This alone represents significant cost savings. Moreover, by doing less roundabout driving in order to service all clients, they save up to 25% on fuel costs and distance traveled. In a short period of time they ended up with a leaner vehicle fleet that meets all fleet management requirements. All this within the 3 months it took to establish interfaces with their ERP, install the system, and run fine tune in accordance with their specific processes.

The transportation costs of a logistic operation are by far the most impactful for a company, particularly if they are running their own vehicle fleet. Costs in question involve acquisition of vehicles, fuel costs, maintenance, idleness, and many others. Some of these are fixed, and there is not much leeway in terms of savings. Others however are variable, and are subject to optimizations and overall rationalizations of the transportation process.

If we were to simplify the entire process, it entails a group of vehicles transporting goods from point A to point B. Except there’s a point C, D, E, and potentially thousands of other points. The complexity adds up very quickly. Not to mention the many real world constraints and various unexpected circumstances.

All this is to say that even in its simplified form, transport routing is a very difficult problem. In fact, it is deemed as one of the most difficult optimization problems in literature based on the sheer number of possible combinations. On top of that add real-world constraints such as multiple vehicles breaking down, roads being inaccessible to larger vehicles, time windows, etc. and you get a challenge to say the least.

A single expert with extensive experience can efficiently plan routes for dozens of customers. Not that large of a number, especially considering in practice you are often dealing with an order of magnitude more customers and vehicles. Moreover, experts are in short supply.And this is where the brunt of process rationalization when it comes to transport of goods lies. By using AI models and metaheuristics you can offload the brunt of the difficult optimization work to a computer. It will run millions of calculations in a short period of time, and deliver an optimized route for all your vehicles and deliveries you have to complete for a given day. Instead of costing an expert to figure out a suboptimal route, a machine can find optimal or near-optimal routes for hundreds or even thousands of delivery points. All this, while accounting for the many real-world constraints such as:

- Vehicle working hours

- Vehicle volume

- Vehicle load capacity

- Vehicle access to customer’s unloading stations

- Blocked roads

- Heterogeneous fleet

- And many others

What can you expect in terms of results? By using a smart routing solution, a large retail chain experienced an up to 30% reduction in vehicles required to complete all their daily operations. This alone represents significant cost savings. Moreover, by doing less roundabout driving in order to service all clients, they save up to 25% on fuel costs and distance traveled. In a short period of time they ended up with a leaner vehicle fleet that meets all fleet management requirements. All this within the 3 months it took to establish interfaces with their ERP, install the system, and run fine tune in accordance with their specific processes. For more information you can visit smartmws.ai or check out our whitepaper — Adaptive multi-phase approach for solving the realistic vehicle routing problems in logistics with innovative comparison method for evaluation based on real GPS data.