smart WMS

Transform Your Warehouse Through AI/ML Technologies

4 min read

•

09 May 2022

The importance of supply chains can hardly be overstated given how critical the proper flow of supplies is to the overall world economy.

In this article we focus on the effects and benefits achieved by optimizing individual links in the chain — specifically warehouses and storage areas.

Even if a large warehouse is operating smoothly, a sudden and unexpected increase in demand can quickly overwhelm day to day operations, cause delays in shipments, and various other problems that lead to disruptions further down the chain.

To alleviate such disruptions, AI/ML and data-driven approaches can advance operations by feeding on historic data and using heuristics and metaheuristics to introduce fully rational and dynamic workflows into warehouses. Ultimately, even a limited number of AI-powered processes can have a significant impact on efficiency and yield almost immediate benefits in terms of cost savings.

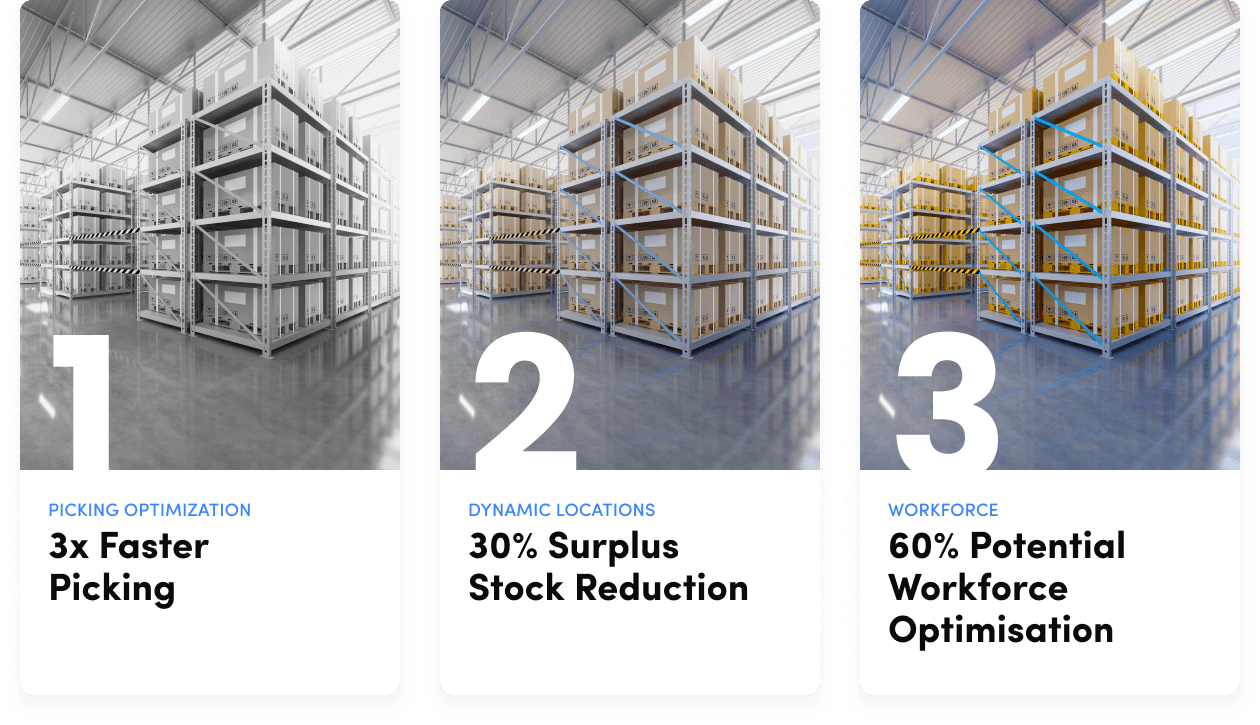

Below, we list 3 optimizations that have proven to work very well in practice.

1. Picking Optimization

State-of-the-art heuristic and metaheuristic algorithms calculate optimal picking paths while enforcing various real world constraints (e.g. goods fragility), allowing your workers to do more while expending less energy. Moreover, proper routing of workers along with a polished scanner app user experience allows you to onboard new employees within a single day and have them quickly achieve full operational capacity.

To reach further depths and truly optimize your picking process, smart order splitting and order batching is performed. Inbound orders are split into chunks that are collected individually by workers according to various configurable criteria (such as sectors the goods are located in). The orders are batched before collection to ensure that they are ready for delivery. The splitting and batching logic is powered by sophisticated algorithms, for instance the Bat algorithm, that ensures you get near-optimal results.

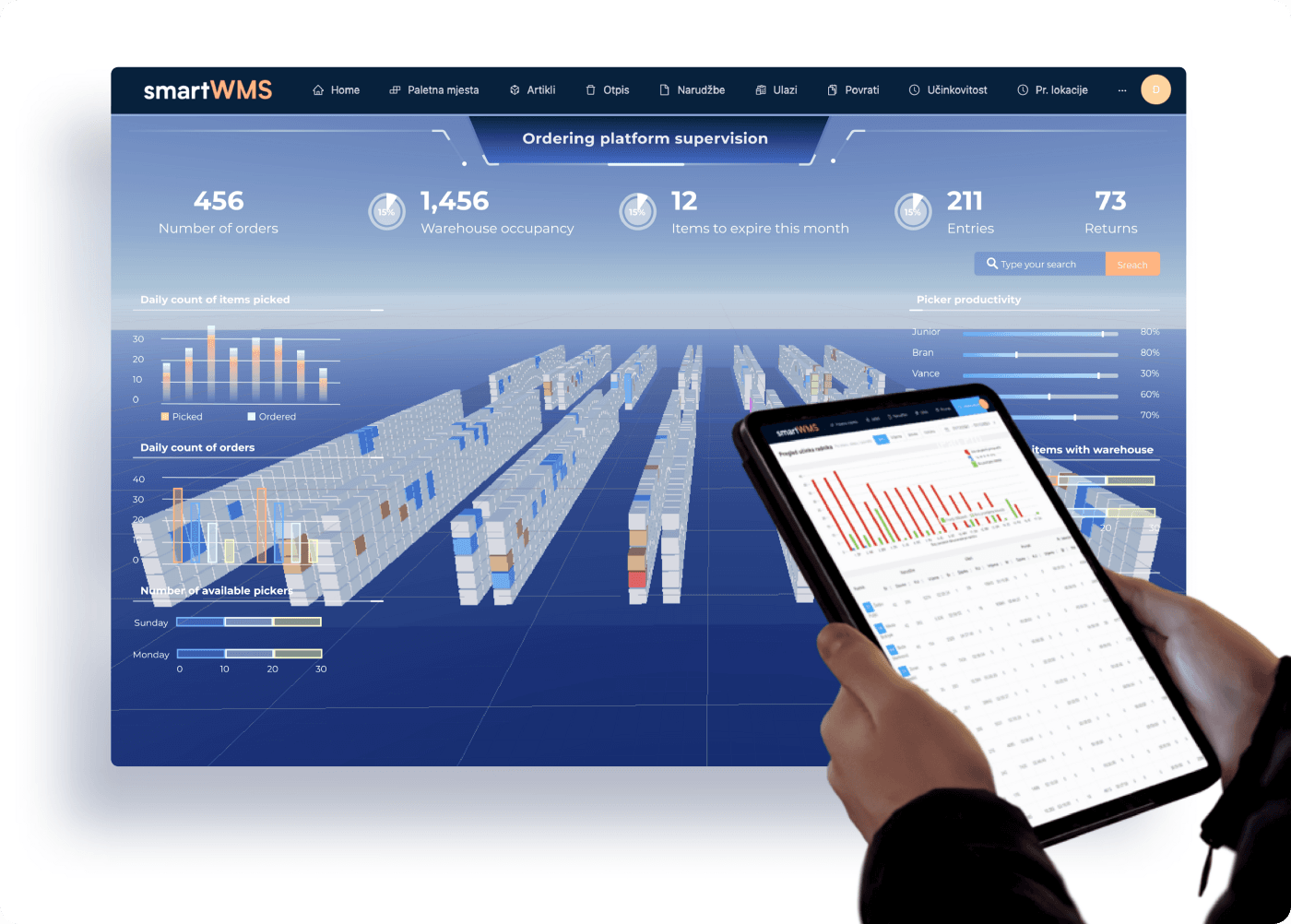

2. Dynamic Optimal Location Recommendations and 3D Vizualization

Through a combination of AI/ML models and expert systems, we constantly recommend favorable locations for best-selling items and movers. This is performed as part of standard transactions, meaning there is no delay in operations or need for routine repositioning of already settled stock.

Having an insight into current stock levels and visualizing placement positions in regular intervals, we get a real-time representation of the warehouse. For instance, during put-away of goods the system recommends optimal locations for each item. If the best matching location is occupied or otherwise unavailable (due to constraints such as weight, safety considerations, etc.), the next best location is recommended, and so on until the goods are properly put away. Similarly, poor sellers will be delegated to locations that are deemed as wanting.

Managers can use a real time 3D dashboard to observe the history of movement of goods, and subsequently the ensuing rationalization of stock positions.

The benefits of well positioned goods are numerous:

- Less travel time

- Goods safety accounted for

- Faster and more efficient put-away process

- Improved space utilization

3. Smart Sales Forecasting Towards Optimal Supply and Stock Levels

Brand managers, when left to intuition and experience, tend to order more stock than actually needed. This makes sense, since it can be costly and damaging to your brand to have your service levels drop due to out-of-stock items, and it is difficult to account for all fluctuations and seasonality. Using an ensemble model based on AI techniques used by Amazon and Facebook, we predict your sales and consequently your stock levels with up to 95% accuracy for most significant portions of your item portfolio (best sellers). Through stock optimization via forecasting, you obtain insight and assistance when creating orders, leading to great potential for savings, and opening options to plan all your processes in more detail and with greater confidence, improving the overall quality and exactness of your operation.

Applied in real world

Processes governed by AI, on average, are executed more coherently than can realistically be expected of individual workers, particularly inexperienced personnel. Of course, a degree of flexibility with respect to avoiding strict enforcement of actions is required, ultimately leaving people with the ability to make the final decision if they deem it the better option.

Our team at InfoStudio has developed a Smart Warehouse Management System that combines innovative technologies and state-of-the-art AI/ML models to convert traditional warehouse operations into intelligent processes. This brings about significant stock reductions, reduction in labor and costs, perishable goods management, full traceability, as well as greater control over the flow of goods and their timely delivery to the customer.

Through synchronous application of more than 10 AI/ML processes, we achieve:

- 60% potential workforce reduction

- 50% average route length reduction for the employees and 3x faster picking

- 30% storage space and stock reduction

- 99.9% data entry and shipment accuracy

- Significant perishable goods loss reduction

- And many other improvements